17th Jan 2019

Closed Cell Polyethylene Foam for Handbag Structure, Stabilising and Interlining

Handbags are something of an essential accessory in everyday life for containing important items and have become a statement piece within the fashion industry. Although it might not be immediately obvious, foam plays an important part in the structure and stability for the posture of handbags, as well as purses, book bags, laptop carriers and nappy bags to name but a few.

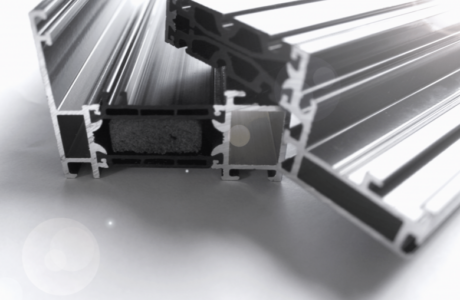

Whilst some lightweight material bags use compressed fleece for their interlining and interfacing, our closed cell polyethylene foam makes for an excellent choice for ensuring the stability and structure of handbags. By giving luxury outer material a more rigid interior to hold its form, the shape and body of a handbag can be designed and styled with the confidence in its framework.

Closed Cell Polyethylene Foam (PE)

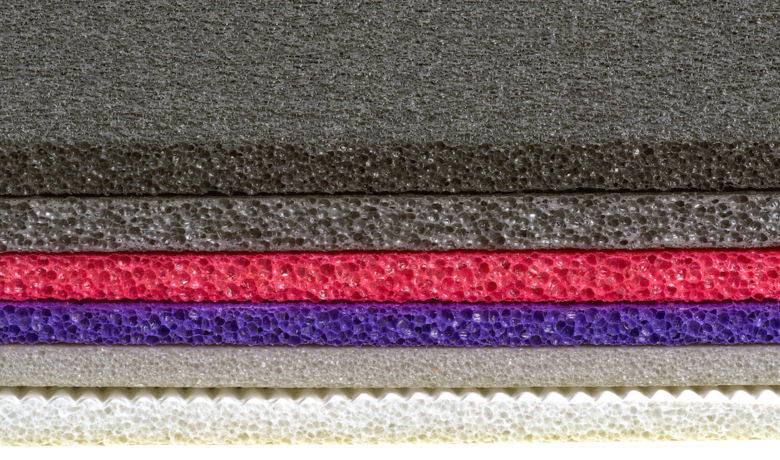

There are many benefits when it comes to closed cell PE foam and one of its most popular points, is that despite being low-cost, it’s high quality and can be produced on mass in sheets and rolls for ease of application. It’s durable and robust so it won’t crack, crumble or become brittle - allowing for the longevity to last in a more regularly used handbag and one that’s often saved for special occasions.

It’s lightweight which makes it perfect for carrying - especially in holiday luggage where weight plays a key role in baggage allowances. They come in a range of attractive aesthetics, are low odour (antibacterial) and have a high strength-to-weight ratio.

Benefit highlights of Polyethylene foam:

- Low cost

- High quality foam

- Lightweight

- Low odour

- Antibacterial

- Range of colours and densities

- Flame retardant

- High strength-to-weight ratio

- Non-toxic

- Thermally insulating

- Resistant to UV, moisture and chemicals

- Waterproof

It’s not just handbags closed cell foam is an excellent candidate for either. Foam is used within purses and wallets to add shape to the outer casing, travel luggage for form and structure, laptop and camera cases for protection and nappy bags for shape, safety and thermal insulation of some of the anticipated contents.

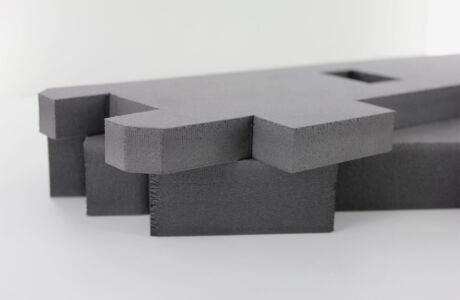

We can split, saw, rout, die cut, water-jet cut, butt-weld, laminate, adhere, thermoform or compression mould and cut to size all of our foams, to create even the most complex shapes and sizes. We can supply our polyethylene foam in sheets, rolls and blocks.

Whatever you’d like to achieve, our expert team can work with you to design and develop products and components, choosing and using the very best materials for the job. Talk to us about your latest challenge today.