21st Mar 2018

The Many Uses of Filtration Foams

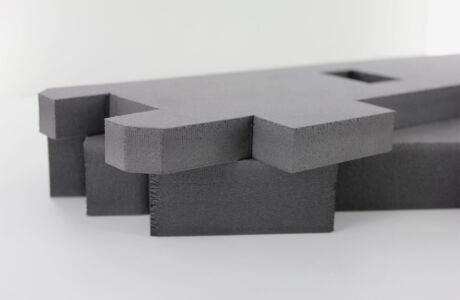

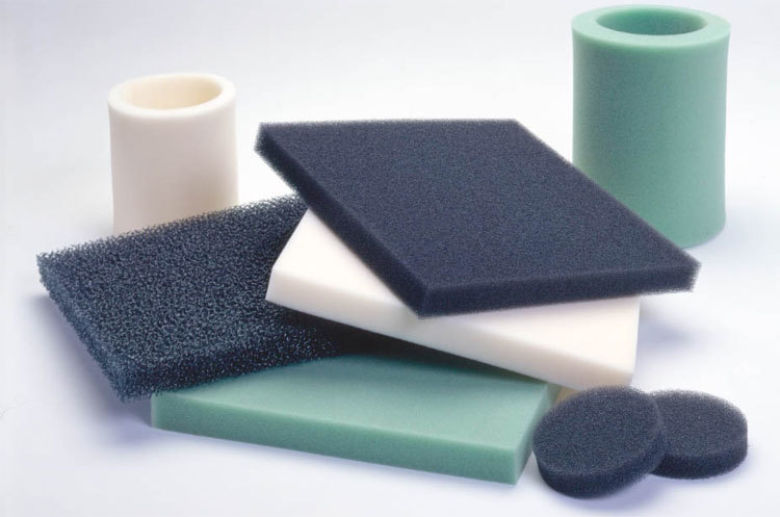

Filtration Foam is Polyurethane based with either a Polyester or Polyether Polyol and created by removing cell membranes from within, through a process known as reticulation. This creates an open, almost net like structure within the foam, allowing for a low flow restriction giving particles the freedom to pass through while dust and other unwanted particles are trapped within the cells of the reticulated foam.

PPI (Pores Per Inch) identifies the number of cells within the Foam. A low count such as PPI 10 therefore means there are less pores within the foam, so cells are larger and open providing a larger space for air particles to pass through. Alternatively, the higher a PPI count the denser the foam becomes meaning less flow and better restriction.

The general purpose for all filtration foams is essentially the same. To filter the particles passing through, such as water or air for example, whilst trapping unwanted particles within the cells of the foam. This can vary based on the application of the foam.

Common uses for filtration foams include:

- Water Filters

- Scrubbers

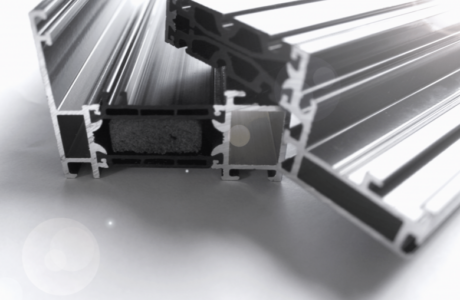

- Speaker Grills

- Tobacco Filters

- Inkjet Cartridges

- Gas Filters

- Face Masks

Here at Zouch Converters, we have been manufacturing and supplying world class filtration foams to industry leading organisations for over a decade.

Whatever your need, get in touch with the experts here at Zouch and we’ll be sure to filter through all your worries and find a solution to your upcoming project.