11th Jun 2018

Sponge Rubber Types, Applications and Industries

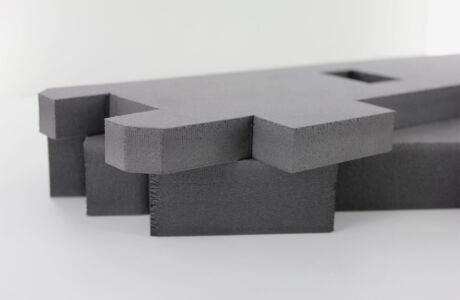

Sponge rubber is a highly versatile material used in a wide range of applications across a multitude of industries. It’s used within a variety of demanding environments and can be made in several densities, is extremely flexible and customisable too.

Our technical team put together a guide to explain sponge rubber types, their product and applications and the most common industries sponge rubber is used in.

Chloroprene / Neoprene Sponge (CR)

Chloroprene / Neoprene is a synthetic, polymerised rubber that is a well established and widely used closed cell material. It can be used in both hot and cold environments for temperature resistance and has excellent chemical, solvent and oil stability.

Due to its flame retardant and water absorption properties, it makes it resistant to degradation and is often popular within demanding automotive applications. Chloroprene / neoprene is flexible, durable and recovers very well under compression.

Neoprene / EDPM Blended Sponge

Neoprene EPDM is a low-cost closed cell foam blend and is often used as a quality general purpose sponge rubber. It’s now more popular than its separate forms (Neoprene and EPDM foam) due to its excellent aging properties and the fact it won’t crack or become brittle.

The blended Neoprene and EPDM sponge is waterproof and so ideal for the sport and leisure industry, as well as the marine and flotation industry too. It offers some fuel, oil and chemical resistance, and is flame retardant to FMVSS302 and UL94 HF 1.

Natural Rubber Sponge (NR) - Open Cell Type

Natural rubber sponge (also known as NR) is a versatile and heavy duty open cell material. It has excellent compression resistance and recover and is anti slip. Natural sponge rubber also offers excellent acoustic isolation and vibration dampening, so it’s perfect for noisy environments with industrial applications or a need for sound control. NR can be found in many day-to-day products such as drum gaskets, mouse mats, tool and die ejection and resilient strips.

EPDM Sponge

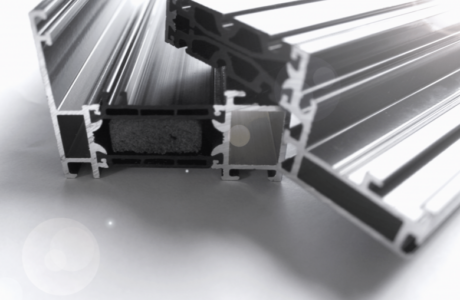

Although the Neoprene and EPDM blend has become increasingly popular, but EPDM on its own is still a firm favourite for a wide range of civil engineering, construction and electrical uses. EPDM is a flexible, low cost closed cell synthetic rubber and is ideal for applications and products like seals and gaskets in the automotive industry.

EPDM sponge has excellent UV, ozone, temperature, weathering and age resistance. It also has low resistance to oils, gasoline and acids. It’s popular for heat insulation seals, roofing, air conditioners and fridge seals.

PVC / Nitrile Sponge

PVC and Nitrile sponge is a soft and flexible premium quality closed cell sponge rubber. It has excellent thermal properties which makes it ideal for applications requiring hot and cold pipe insulation. Its flame retardancy conforms to BS476 Class 0 parts 6 and 7.

Only minimal pressure is needed to form a resilient seal and it’s easily fabricated into washers, pads, gaskets, strips, sheets and semi-circular tubing. It’s both oil and chemical resistant and boasts good sound absorbency too. PVC / Nitrile sponge’s typical uses are for heating plants, hot and cold water treatment, duct insulation and automotive gaskets.

Vinyl / Nitrile Sponge

Vinyl / Nitrile sponge is often used for protection wear such as police and military stab vests and equestrian body protectors. It’s perfect for high impact cushioning and resistance and has powerful vibration dampening properties. The sponge is a closed cell synthetic rubber which means it’s both flexible and comfortable for the wearer.

As one of Europe’s leading, fastest growing independent converters of rubber, foam and non-metallic materials, we’re committed to delivering industry leading products proven to be durable, profitable and technologically advanced. In fact, all of our sponge rubbers combine strength and durability with optimum resistance to ageing, weathering, UV and ozone.

Our sponge rubbers can be prepared and supplied as:

- Rolls

- Sheets

- Strips

- Pads

- Die-cut gaskets

- Cross-wound spools

We can also produce our sponge rubber with or without a pressure-sensitive adhesive backing, so they’re easy to adapt for your specific task.

Whatever you need to achieve, you’ll have our expert support in choosing and using the very best product for your project. Get in touch with our technical team to discuss your needs and what product is most suitable to achieve your end result.