26th Feb 2018

Specialist UV Stable Tapes Transform Solar Panel Market

As fossil fuel prices continue to rise, so too does the promise of alternative sources of power. Solar panel production in the UK is on the up, with solar arrays dominating landscapes nationwide – we have developed a range of specialist UV stable tapes designed to be an integral part of solar panel production.

Enthusiasm towards solar arrays has increased as they have a much more localised impact, ensuring less noise and less ground disturbance than wind turbines. The large-scale push towards renewable energy development spurred Zouch Converters to develop a range of highly specialised adhesive foam tapes and films that are designed specifically for the solar panel market. The company's entry into the renewable energies field back in 2011 was part of its on-going commitment to a sustained allegiance to the environment.

The rising cost of fossil fuels has stimulated growth in alternative sources of power. Unlike fossil fuels, renewable energy has less impact on the environment and ensures a reliable and sustainable alternative. Zouch Converters offer a range of adhesive tapes and films that are utilised within, during and after the solar panel production process. Adhesive tapes are increasingly employed as an alternative to mechanical fastenings as they are secure, quick and easy to use and lighter in weight compared to traditional methods of fixings.

The Zouch range of solar panel tapes boasts:

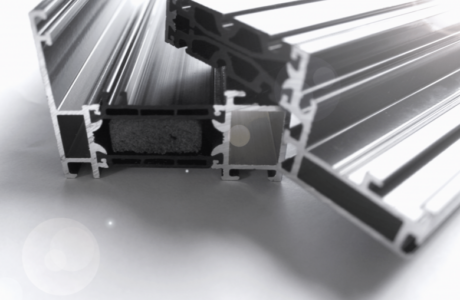

- double-sided self-adhesive mounting tapes for frame sealing of solar thermal collections

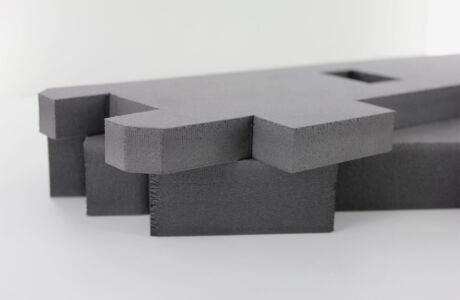

- distance shipping pads coated with a low tack, peelable adhesive on one side, providing a perfect transport protection for delicate surfaces

- double-sided self-adhesive mounting taes for junction boxes underneath solar panels which requires no curing times

- double-sided self-adhesive bumpers made of TPE (Thermoplastic Elastomer) which are used as spacers to give initial fixation and provide a properly sized gap for the sealant, when the solar modules are being bonded onto a base construction by means of a one component or two component liquid sealant

These specialised materials are designed to last the lifetime of the panel and the skilled team are at hand to correlate technical specification to exact application.

We are proud of the steps we are taking to pursue green issues. With a reliable alternative to mechanical fixings we are confident we can reduce your carbon footprint and drastically diminish man hours to further advantage your green cause.

Get in touch with our expert team to discuss how we can help you go green!