16th Jul 2018

Closed Cell Polyethylene Foam for Packaging and Case Inserts

If you’re looking to protect items within loose packaging more isn’t always the answer. The key is in reviewing the product by its size, shape, sensitivity and fragility. Only then should you decide on the amount and density of the foam that is required.

The key is to ensure that foam isn’t too dense or tightly packed, as any impact to the package will transfer the energy of the shock directly to the product itself. Too much foam protection could cause damage to the item or effectively prompt electrostatic discharge (ESD) to electrical items.

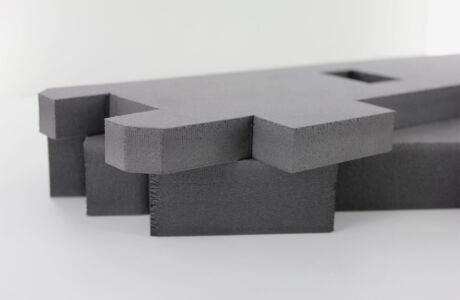

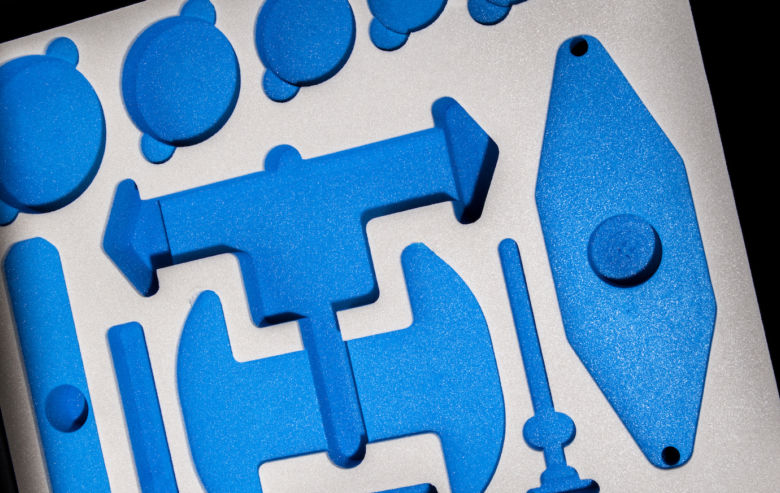

Why we favour die cutting

Die cutting allows for the mass production of cut-out shapes bespoke to your requirements for packaging and inserts, and means that the exact same dimensions can be repeatedly cut for ease of manufacture.

That means that all foam inserts for cases and packaging are tailored to the item you’re looking to protect for transportation and display.

Why choose closed cell foam

Padding is achieved with rigid foam that fits tightly around the product to keep it secure. Single sided adhesive tape is often used to keep the foam fixed in position, too.

Polyethylene foam, commonly known as closed cell foam is a rigid foam that is shock absorbent, thermally insulated, waterproof and perfect for packaging. Its anti static properties prevent damage from impact and vibration.

Other options such as adhesive tape that can be laminated to the die-cut foam to keep it in place or self adhesive foam tape, can also be used a solution to provide cushioning, insulation, slip resistance and absorb vibrations.

As well as die cutting, we also offer waterjet cutting, laser engraving and routing.

Waterjet cutting

Waterjet cutting is used in a range of industries but is more commonly known for aerospace for cutting, shaping and reaming foam material.

Laser engraving

When laser engraving no pressure is applied to the foam material, saving on time and money, and the quality of the finished piece.

Routing

Routing works on a numerical basis and is great for detail work and pattern, as well as lettering and adding different depths to inserts.

Common packaging and case insert applications for protection:

- External hard drives

- Computer hardware

- Gift items, gift sets and gift boxing

- Jewellery

- Glassware and ceramics

- Watch cushioning

- Box sets (such as bottle openers, hip flasks, tie clips, cufflinks)

- Luxury items (such as aged whisky bottles)

- Beverages

- Photo frames

- Mirrors

Other industries closed cell foam is used in for protection:

- Aerospace (interior and packaging)

- Transit packaging (for low odour, non toxic items)

- Case inserts for military weapons and personal protection

- Construction (thermal and sound absorbency)

Zouch have been supplying packaging solutions for over 20 years and have a wealth of knowledge and experience when it comes to protecting items. Whether that’s for transport, keeping items in place for display or ensuing electrical parts are protect from electric charge and static, we can work with you from inception to end solution.

Whatever you’d like to achieve, our expert team can work with you to design and develop protective components and inserts, choosing and using the very best materials for the job. As well as die cutting we can split, saw, rout, water-jet cut, butt-weld, laminate, adhere, thermoform or compression mould all of our foams to create even the most complex shapes and sizes.

Speak to us about your latest challenge and we’ll take an unbiased view to help you achieve the very best outcome for your product packaging.