26th Apr 2018

Adhesive Tape for Bonding, Mounting, Fixing and Joining

Adhesive tapes provide multiple benefits as an alternative method to traditional assembly, such as welding, screws, bolts and soldering. An adhesive tape will offer a consistent bond thickness and size, and can be especially useful to those who need to bond textured, rough and irregular surfaces.

The Benefits of Adhesive Tape

- Increases manufacturing efficiency

- Reduces assembly time

- Thin, easy and quick to apply

- Cost effective

- Consistent

- Better looking finished products

- Adaptable

- Uniformity for thickness and gap filling

- Versatile and resilient

Not only do adhesive tapes come in a variety of strengths for matching against a range of substrates, they’re also available in different formats dependent on the user’s design requirements.

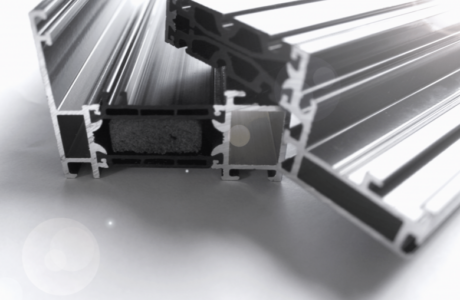

Substrate Types

- Metal

- Traditional materials

- LSE plastics

- Engineered plastic

When it comes to choosing an adhesive tape to bond with, the material surface must be considered and if the tape will bind well with it. That can be dependant on the surface energy, matter, texture and cohesive strength required due to the stress on an adhesive joint. Common stresses that can occur include peel, shear, cleavage and tensile.

Common Assembly Types and Applications

Aerospace

Adhesive tapes are often used within the Aerospace industry for protection parts of aircraft wings and the bonding of different indoor situated materials. It’s popular for aircraft floor and wall panel attachments, and metal and plastic decorative trims to use adhesive tapes so that joins are not always seen, making the interior look more aesthetically pleasing to the eye of passengers. Adhesive tape is also used in overhead stow bins holding luggage and within the structure of passenger seating.

Automotive

When it comes to the automotive industry, adhesive tapes are more often used in the side and roof mouldings of the vehicles body. It’s also a popular means to join inner and outer tread plates (both front and rear), spoilers, bumpers, internal rear view mirrors, registration plates and badges. The use of adhesive tape largely decreases assembly time when the tape can simply be applied by the pressure of a hand, and it’s more cost effective than welding materials.

Electronics

Adhesive tape is often used in the applications of electronic displays, such as the display on the front of a washing machine, oven or microwave. As adhesive tape isn’t just supplied as rolls, it makes it a more accessible means of joining two materials, whilst ensuring better aesthetic for the consumer. All can be supplied in rolls, die cut pieces, large or small sized bobbins, sheets or strips.

Craft

The craft industry is a popular one for adhesive tapes when it comes to creating more attractive and memorable occasion cards. They’re often used for giving cards a “3D effect”, with 3D slogan banners, 3D perspectives and pop outs. They’re perfect for scrapbooking, papercraft, adding embellishments and card making.

Types of Adhesive Tape

Double Sided Pressure Sensitive self Adhesive Tape

We have an unrivalled range of pressure sensitive self adhesive tapes that have been handpicked from the world’s leading manufacturers. We can offer them in single or double sided formats, too. They’re specialist, high-performance products, and made using a range of solvents from water-based, hot-melt or rubber based technologies. Each one offers specific technical capabilities, so across the range, you’ll find a choice of adhesive strengths, bonding abilities and price points, with tapes suitable for different conditions or application techniques.

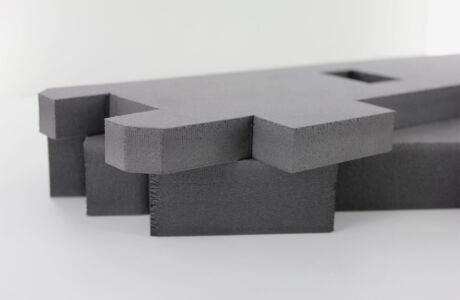

Double Sided Self-Adhesive Foam Tape

At Zouch, we’ve developed a high-performing range of self-adhesive tapes made with sponge rubber or technical foam. They’re suitable for a wide range of uses, they have excellent sealing and insulation properties, protect against water, air, dust, noise and weather damage. We offer our foam tapes in soft, medium and firm-closed cell foams and sponge rubbers, with a variety of substrates, adhesives and liners.

Each Zouch tape is pressure sensitive, easy to apply and clean to use, with no drying time. They’re available as sheets, log rolls, slit rolls, die-cut shapes, gaskets or washers – all designed to be economical, consistent and highly effective components you can rely on in even the most demanding situations.

Which one you choose will depend on the materials you need to bond and the environment you’ll be working in. We’re here to help, with an expert technical team who’ll give you the unbiased advice and support you need to make the right choice for your specific challenge. To talk to us about your project, just get in touch.